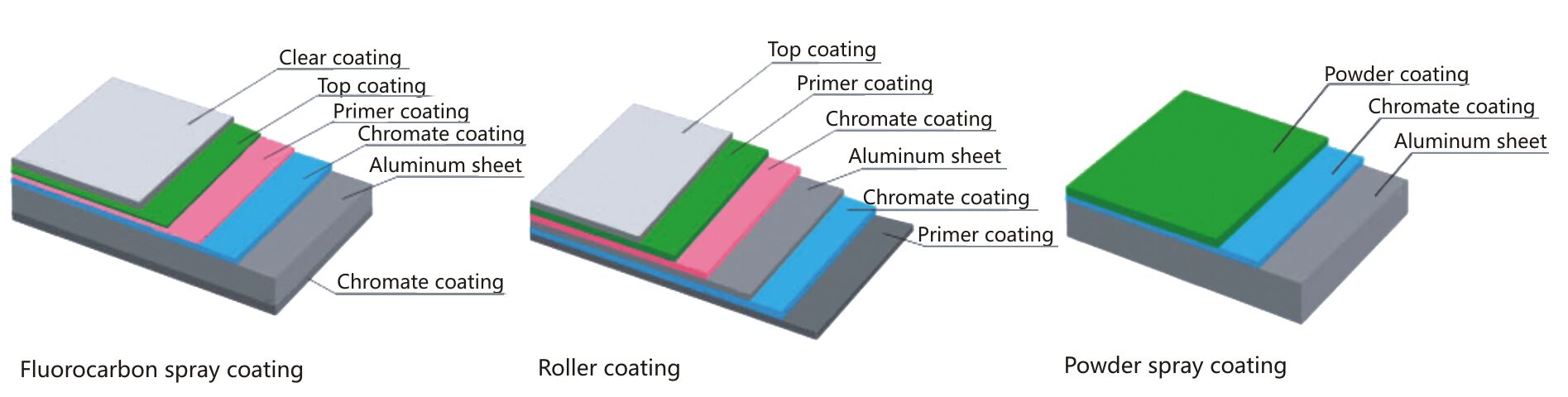

The powder coating has good performance of anti corrosion high adhesion and thick coating film but it tends to discolor color fade if exposed to sunlight for a long time in the exterior area.

Polyester powder coating vs pvdf.

Coatings made from polyvinylidene fluoride resin nch 2 cf 2 baking ch 2 cf 2 n pvdf as the base material or with metal aluminium powder as the colour material fluorocarbon matrix is chemically bonded by fluorine carbonization whole bond.

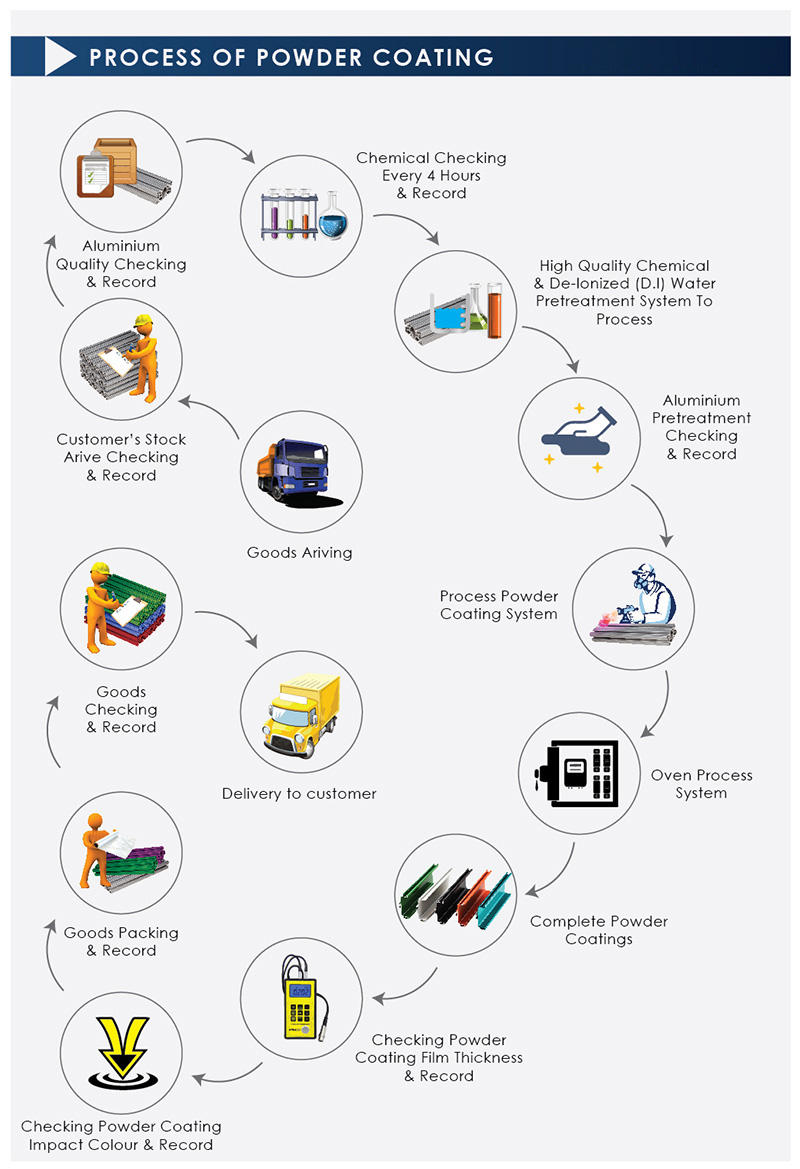

It is a powder that is easy to use and adheres to metals very well.

Pvdf is a premium paint finish as compared to polyester suitable for all profiles tropical tile standing seam and antilles including soffits under ceiling and wall cladding.

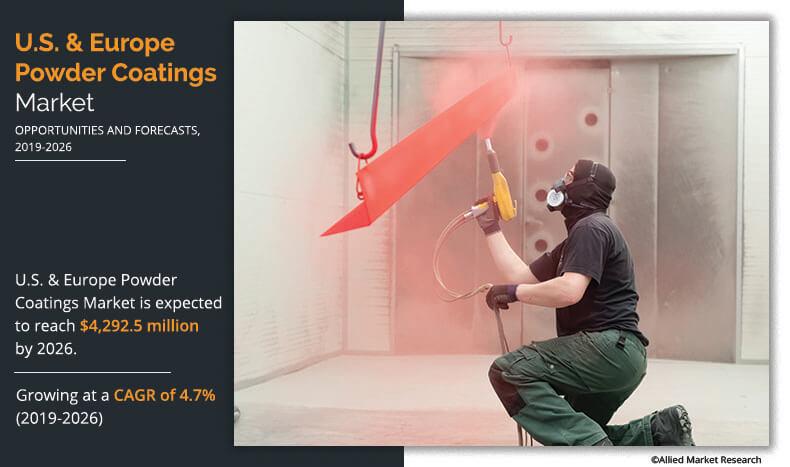

Overspray can not be recovered and becomes hazardous waste no loss of powder materiel due to evaporation of solvents.

Powder coatings are available in numerous choices and a wide variety of colours textures finishes.

Pvdf liquid coatings economic considerations powder coating liquid painting average material efficiency up to 95 of material sprayed.

Average material efficiency is only 35.

Epoxy powder coat one disadvantage of epoxy powders is their inability to weather well.

After natural leveling drying of pvdf the coating film is very thin.

It is normally cost effective.

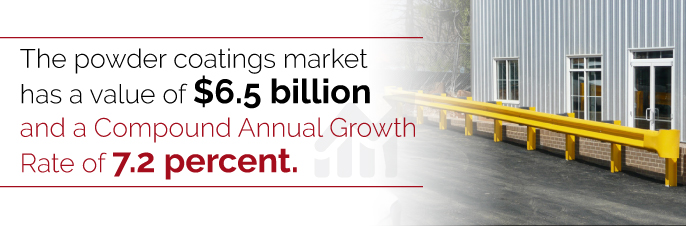

Powder coatings are stronger than pvdf coatings.

Tgic tri glycidyl isocyanurate and non tgic which is also known as tgic free or sometimes a primid.

Excellent adhesion can be obtained through pretreatments of the metal involved including sandblasting and phosphate coating.

Overspray may be reclaimed.

Hence it will provide better resistance to the effects of uv light.

Powder coatings are stronger than pvdf coatings.

Anodized polyester and pvdf.

Pvdf fluoropolymers always need a primer beneath them whether liquid or powder and are.

Pvdf coating is more expensive than powder coating.

Anodized and polyester coatings are best for handrails and storefront.

When comparing polyester vs.

Pvdf coatings have higher durability than powder coatings.

The test result proves that the stability and durability of pvdf coatings are 30 80 higher than the other two coats.

There s a test on pvdf coatings super durable powder coatings and exterior powder coatings.

Drying of powder coating is mainly by baking.

Powder coating is environment friendly.

Pvdf coatings are available only in matte finish in order to get super gloss more layers of coating have to be added resulting in an increase in cost of material and application.

Pvdf has better colour fastness than polyester.

It is useful for antimicrobial coatings.

The two most common types of fluoropolymers found in powder coatings are feve and pvdf.

Pvdf coatings are the finest for metal roofing and curtain wall components.

Humidity heat and oxidation cause the powder coating to crack.

Powder coatings are available in numerous choices and a wide variety of colours textures finishes.

Pvdf powder coating s vs.

The two most widely used types of polyester powder.